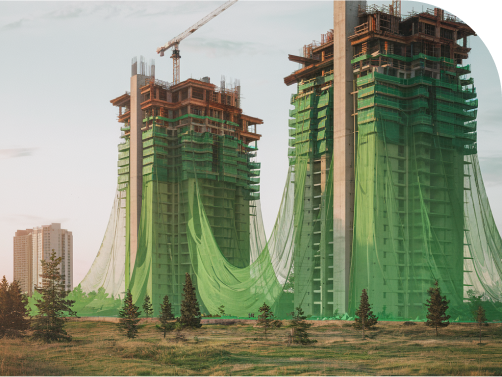

Construction

Our commitment to precision and efficiency at every stage ensures that all fabricated components are delivered on schedule and in full alignment with project requirements to provide our clients with reliable and high-quality results.

Our commitment to precision and efficiency at every stage ensures that all fabricated components are delivered on schedule and in full alignment with project requirements to provide our clients with reliable and high-quality results.

Our fabrication services encompass a broad range of construction needs, from new builds to facility enhancements. We apply advanced methodologies and rigorous quality standards to ensure that every component adheres to industry regulations, fulfills project-specific criteria, and enhances overall operational effectiveness.

Our fabrication services for onshore oil and gas facilities focus on producing components and structures that facilitate efficient extraction, processing, and transportation. We fabricate items like pressure vessels, pipelines, and modular skids, each designed to withstand extreme conditions and ensure safety in high-stakes environments.

For pulp and paper facilities, we fabricate equipment that addresses industry-specific requirements, such as resistance to moisture and corrosion. This includes fabricating digesters, dryers, boilers, and other essential machinery. Each component is designed for durability, supporting smooth, high-output plant operations over extended periods.

Our expertise in power plant fabrication ensures that infrastructure components—such as turbines, boilers, piping systems, and structural supports—are manufactured to withstand intense heat, pressure, and continuous operation. This precision fabrication is essential for the high-performance standards of power generation facilities.

Refineries demand precise, robust fabrication for equipment like heat exchangers, reactors, distillation columns, and storage tanks. Our team focuses on creating components that enhance the refining process, maintaining operational efficiency and safety within high-risk environments.

We provide tailored fabrication solutions for various industrial and petrochemical applications, focusing on equipment resilience and compliance with stringent environmental and safety standards. This includes fabricating storage vessels, pressure systems, and reactors critical for petrochemical processes.

For new, undeveloped sites, our fabrication team manages the construction of all necessary equipment and platforms from the ground up. We fabricate infrastructure for pipelines, skids, and structural frameworks essential for new industrial facilities, ensuring all components are ready for seamless integration during installation.

In platform projects, particularly in offshore oil and gas fields, our fabrication services include producing load-bearing structures that adhere to rigorous safety protocols. Our team ensures that each platform component, from decks to support frames, is fabricated for long-term stability in challenging environments.

Jackets (substructures for offshore platforms) and umbilicals (cabling systems for subsea control) require high-strength materials and precise fabrication techniques to perform reliably underwater. We engineer these components for maximum durability and efficiency, helping support long-term offshore operations.

Our fabrication team provides tailored solutions for brownfield projects, upgrading or modifying existing facilities to extend their lifespan and meet current regulatory standards. We fabricate replacement parts and structural enhancements that integrate smoothly with existing systems, minimizing downtime and ensuring the facility remains operational during upgrades.